Visualization, PLC programm and modernization of 12 die casting magnesium machines. We carried out the project as a subcontractor of NTP company, Kedzierzyn-Kozle, Poland. One of the project’s task was also starting the machines in Morelia, Mexico. The final clients were the TMG and Manufacturas de Magnesio de Mexico, S.A. de C.V. The machines were controlled by Siemens S7300 PLC. The visualizations were written in Delphi (Object Pascal), and overriding SCADA in WinCC. The machines produce the magnesium steering wheels for Ford.

Creating a PLC programms for AudiTT shock absorbers production line. This project was carried out for Automatyk Projekt, Rybnik, Poland. The equipment was produced by Mandragon Assembly, Stockach and the final client was Delphi Poland S.A. Krosno division. Each of the assembly stands was controlled by Allen Bradley 500 PLC driver. The platform for visualizations were Allen Bradley operating panels.

Modernization of PLC programm and creating a new visualization for a machine producing crossheads for Audi DL501 gear box. This project was carried out for rw automation, Ried, Germany. The main cause for the modernization was replacing PLC and operating panel, and the requirement of the machine’s better effectiveness. The project also involved modernization of two ABB welding robots. The final client was KOKI TECHNIK Shifting Systems GmbH, Konstanz, Germany. During the project we used PLC VIPA 300S driver and VIPA touch panel. The visualization was made in zenOn system. The machine consists of a turntable, catchers, holders and two ABB IRB 1400 welding robots with automatic TCP checking.

Software modernization of the Aasted assorted chocolates production line. We carried the project out as a subcontractor Automatyk Projekt from Rybnik,Poland. The final client was ZPC Mieszko S.A.Raciborz,Poland. The line is controlled by Allen Bradley 5000 PLC. Visualizations work with touch panels by the same producer.

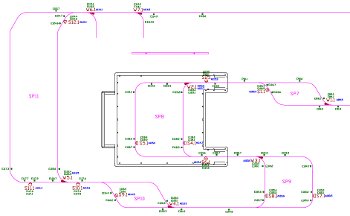

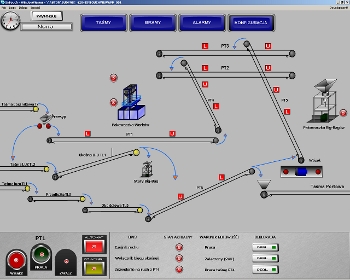

Constructing the PLC programm and visualization of a belt conveyor flight system in a nitro-chalk packing department (ZAK building 420). The project was carried out by 3Electrons as subcontracting for Energoaparatura, Katowice, Poland. An additional task was to connect the already existing controlling system of the old packing department with the new one. We managed to do this without any production down time. The final client was Zaklady Azotowe Kedzierzyn S.A. The PLC was Ge Fanuc 90-30. The visualization was created in Wonderware In Touch10.

Modernization of PLC programm and visualization of a transport line Power and Free for an aluminium components powder painting line. We realized this project for Albea Aluminiumbearbeitung Gmbh from Friesenheim-Schuttern, Germany. The main reason for the modernization was the change of route and appliances of the transport line.All the changes in the equipment were done by the producer of the line, CSF Forderanlagen Gmbh from Oberboihingen, Germany. Both the modernization and starting the line were done in a very short time, during the New Year break, without long down time.The transport line is controlled by Siemens S5 PLC. The visualization works with Siemens OP 17 panel.